Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

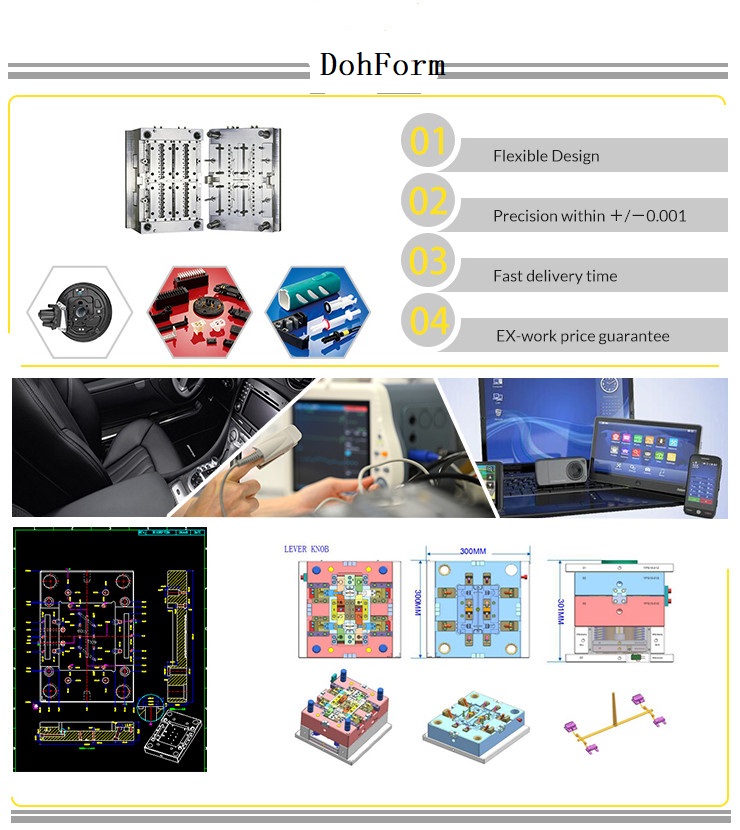

Brand: DoHform

Place Of Origin: China

Forming Method: Plastic Injection Mould

Product Material: Rubber, Plastic

Product: Vehicle Mould, Household Appliance, Household Product

Packaging: Standard exported Wooden box packed, Fumigation process(upon required)

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability:

Port: Shanghai,Ningbo,China

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CFR,CIF,EXW

Acoustic palstc products injection mold

Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend the best tooling option for you.

It can take 3 to 6 weeks to have the mould tool manufactured depending on the part's complexity, size and the number of impressions/ cavities (single or multiple). After we receive your final approval on the tool preliminary design, you can expect delivery of T1 parts within 3-6 weeks. And during mold building process, mold build Weekly Update will be provided to you every week for your better understanding of the manufacturing progress in our work shop.

Product Categories :Camera/ Mobile / Computer Parts Mold

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.