Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

![]() February 09, 2023

February 09, 2023

Why use aluminum parts to process precision parts?

What is cnc processing?

Good Quality Cnc Aluminum Parts machining is the most commonly used subtractive production technology. In this type of manufacturing, different types of cutting tools are used to eject material from solid material to create parts based on computer-aided design models. You have to start with an oversized piece of material that you have to cut away so that you are left with what you want. The simple resemblance is designing a chunk out of the material. You can whittle away marbles until you come up with a masterpiece.

This production program can be used for the processing of plastics and metals. CNC machining, which also stands for computer numerical control machining, involves the programming of computer software to issue automatic commands to the functions of manufacturing equipment. Different complex machinery can be operated using this processing method. Another benefit of this process is that it ensures 3D cutting is done through a series of commands.

During CNC milling, the part is held firmly on the surface and material is removed using a rotating cutting device. In turning, the workpiece is held firmly on a rotating chuck, and material is removed using a stationary cutting device. Different materials that can be produced by CNC machining include brass, aluminum, stainless steel, and nylon.

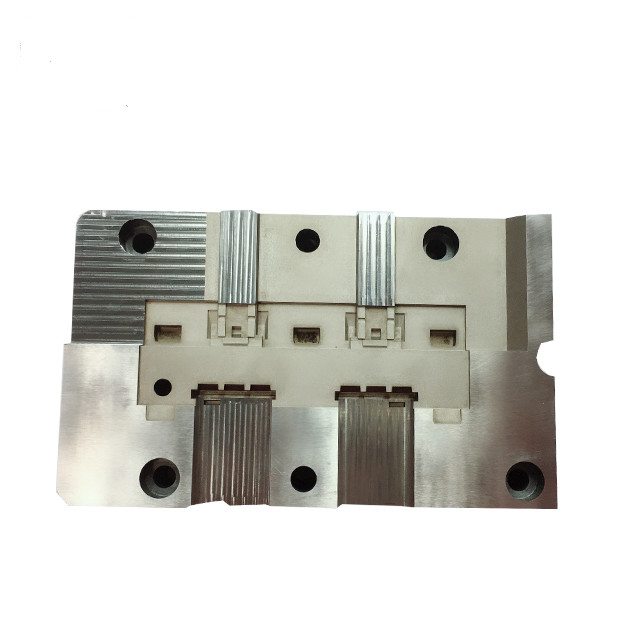

Good Quality CNC Aluminum Parts

Aluminum is one of the most commonly used machining materials because of its excellent mechanical properties. Some of these properties include softness, economy, durability and corrosion resistance. Precision machined CNC aluminum parts have become commonplace in recent days, especially in military, medical, aerospace and industrial engineering. Advanced technology and CNC machines are used to CNC aluminum as they require precision.

One of the benefits of aluminum is that it is a versatile material that can be used in a variety of fields. It has outstanding features such as lightness and durability. Aluminum also needs absolute brilliance to be applied in different fields such as aircraft manufacturing, power generation, and automobile manufacturing. In the automotive industry, it can be used to make reflectors commonly used in automotive lamps.

Why use aluminum?

Professional CNC Aluminum Parts are generally less expensive because they can be machined in a fraction of the time compared to other metals such as steel. They also require no additional finishes. Small amounts of zinc, magnesium, copper, and other materials are added for strength, since pure aluminum metal is usually soft. When exposed to the atmosphere, a thin protective layer is formed, making it resistant to corrosion and reducing the chance of its surface rusting. It is chemical resistant, easy to process, and has great strength for its weight.

Machined Parts: Aluminum and Steel

Aluminum is about one-third the weight of steel. It also conducts heat and electricity easily, which makes it a perfect material for steel sinks. Aluminum reflects heat and light, is malleable and non-magnetic. Some companies specialize in custom Professional CNC Aluminum Parts. This is mainly because they are economical and lightweight. Professional CNC Aluminum Parts are generally less expensive because they can be machined in a fraction of the time compared to other materials such as brass and steel. It also doesn't need new finishes.

Benefits of Reliable CNC Aluminum Parts

CNC machining of aluminum has several benefits. They include:

1. Easy to bend

One of the benefits of using the CNC machining process to create Reliable CNC Aluminum Parts is that they can be bent easily. Unlike steel, aluminum material can be easily turned during machining because the thickness of this material allows various forming methods to be used appropriately. The various shapes of aluminum CNC parts are best achieved by pressing and machining.

2. Easy to process

Another benefit of the Reliable CNC Aluminum Parts process is that the material can be easily manufactured by stamping, folding and drilling. You can use it to form parts of various shapes according to your needs. The energy used to process aluminum is much lower than that of steel.

3. Low temperature resistance

Aluminum material is low temperature resistant. We all know how fragile steel is, especially in welded sections or in low temperature environments. Compared with steel materials, aluminum materials can be easily processed at low temperatures.

4. Custom Finishing

Aluminum can be customized according to customer's requirements after finishing. There are a few things you can do to give it that perfect custom look. Reliable CNC Aluminum Parts can be plated in various colors according to your requirements. Some colors you can try include black, blue and green.

CNC machining of aluminum is subject to some changes, especially in design and specification, which gives it the flexibility to make a quick transition by initiating a new review and approval process. It's also possible to go back to old procedures when you need to, reliably making common quality in aluminum removal projects that come up. Some typical aluminum alloys include Aluminum 2024, Aluminum 5052, Aluminum 7075, Aluminum 6063, and Aluminum 6061.

In conclusion

Thanks to the CNC machining process, the manufacture of Reliable CNC Aluminum Parts is a breeze. The precision you get when extracting such fragments is the main reason many people find this process useful. One can obtain complex parts from the CNC machining process. You will enjoy the simple nature and level of security of this method making it the best choice compared to other methods. You should try CNC machining in the production of aluminum parts and enjoy the benefits and convenience.

The above is the Why use aluminum parts to process precision parts? we have listed for you. You can submit the following form to obtain more industry information we provide for you.

You can visit our website or contact us, and we will provide the latest consultation and solutions

Send Inquiry

Most Popular

lastest New

Send Inquiry

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.