Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand: DoHform

Place Of Origin: China

Forming Method: Plastic Injection Mould

Product Material: Rubber, Plastic

Product: Vehicle Mould, Household Appliance, Household Product

Packaging: Standard exported Wooden box packed, Fumigation process(upon required)

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability:

Port: Shanghai,Ningbo,China

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CFR,CIF,EXW

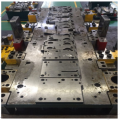

Metal Stamping Tooling /Die for Auto Parts/Components

1. Start from part design analysis.

2. Mold design drawing and DFM report available so you can see how is the mold going to be before mold making.

3. If product is complex, moldflow report will be present as well.

4. Indoor workshop ensures you high quality under good control.

5. Normally it takes 15-60 days to make mold, precise time depends on complexity of design.

| Name | High quality Precision progressiveAuto Parts Stamping Dietool |

| Mould material | SKD11,SKH-9,Cr12M0V,ASP60, CD650,V30,KD20, NAK80,XW-42,S45C,etc. |

| Product material | Steel,copper,brass,bronze,etc.Or as customer's requests. |

| Processing equipment | CNC machine,Automotic lathe machine,EDM machine,Wire-cutting machine,Milling/Grinding machine,Punching/Drilling machine,Ultrasonec cleaning machine,injection machine,punching machine,etc. |

| Detection equipment | Projector,Calliper,Height gauge,Screw gauge,Hardness gauge,etc. |

| Design software | UG, PROE ,CATIA, SOLIDWORK, CAD,etc. |

| Mould life | 1-30million shots |

| Specification | 11 years machining parts processing experience;Precision tolerance less than 0.001mm;Depends on customer’s requirements. |

| Delivery | Shipping test sample in 30 days after receive the payment,or according to customer's requests. |

| Payment terms | T/T, L/C,D/A,D/P,Paypal, Western Union,etc. |

| Package | PE bags add export carton for products,wooden case for mold,or as customer's requirments. |

A) Before sales Service

B) Production period service

C) After sales service

Product Categories :Metal Parts For Car Interior

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.