Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand: DoHform

Place Of Origin: China

Forming Method: Punching Mold

Product Material: Metal, Steel, Aluminium, Iron, Copper

Product: Vehicle Mould, Household Appliance, Household Product

Packaging: Standard exported Wooden box packed, Fumigation process(upon required)

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability:

Port: Shanghai,Ningbo,China

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CFR,CIF,EXW

Experience custom precision sheet metal stamping mould

Mold Desigh Solutions

Before mold fabrication, we will analyze the customer's drawings and provide design change soluction if necessary. Mold design will be sent for approval before each mold building. All of our tools are constructed to rigid DME and Hasco mold standards.We utilize only high-grade mold steels from companies such as Uddeholm and International mold steel(P20,H13,2344,420,S-7,718H,S136,etc).For the hot runner system,we use MoldMaster,DME, Husky,Yudo,etc.

2D + 3D drawing Design:

| Product name | 11 years experience custom precision sheet metal stamping mould maker |

| Tooling steel material | Depend on product, we help customer to choose the suitable material. Commonly used material as below: Carbide(CD650,V3,KD20), ASP-23, ASP-60, S55C---45#55, SKD11. |

| Steel ofMold Base | Depend on product, we help customer to choose the suitable material. Commonly use S45C. |

| Mould Standard components | HASCO, MISUMI, Meusburger, DME, etc. |

| Die concept | 2-Plate Day, 3-Plate Day, Module Day |

| Mold life | Depends on the steel material and your requests. Commonly used: 50 Million to 300 Million Times |

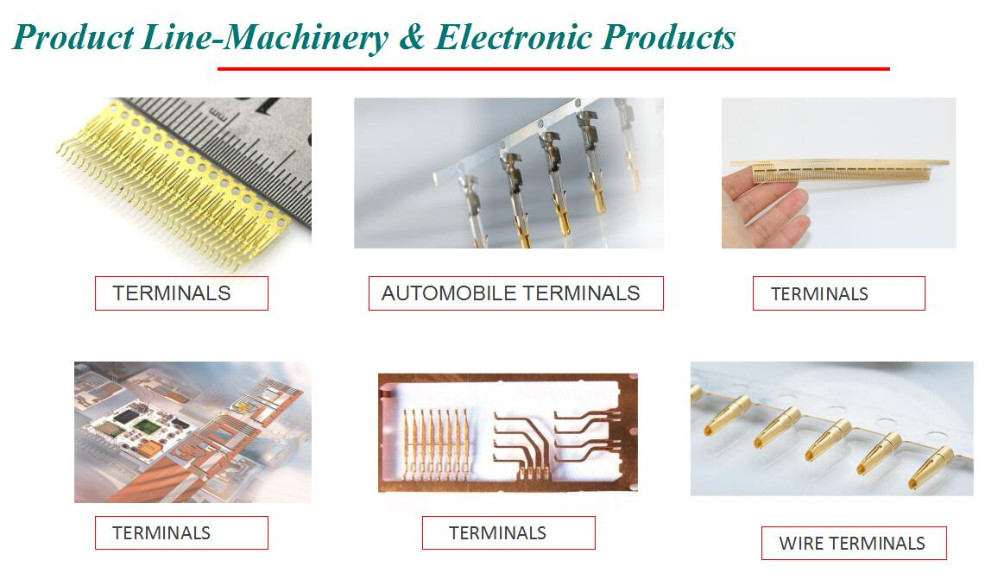

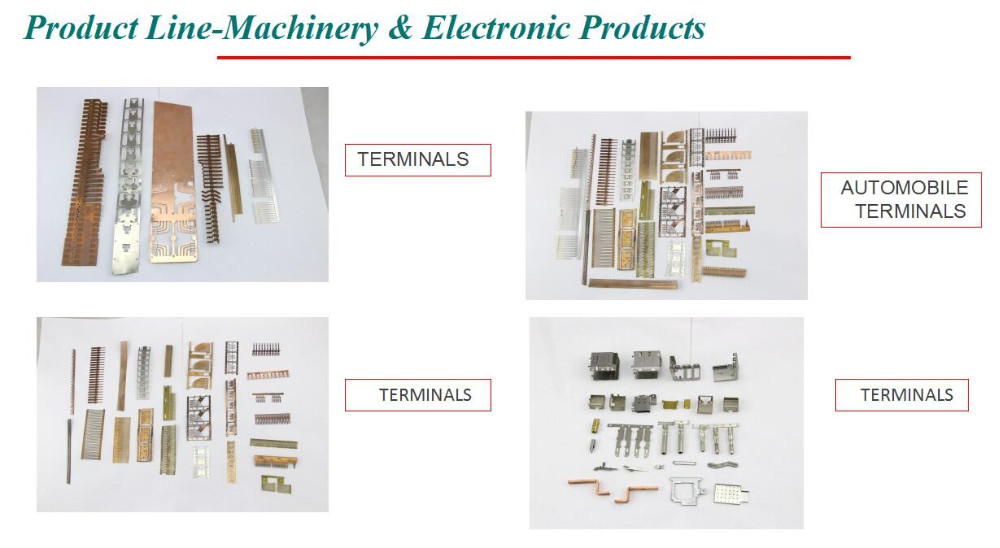

| Stamping Product | PC Terminal, Power terminal, Press-Fit Terminal, Lead frame, SIM Spring,Connector Shield, Battery, Metal USB shell, custom stamping. |

| Surface finish | Depends on your requirements. Commonly: Texture Hatching, EDM Hatching, plating, Polishing, Diamoud Polishing, Mirror Polishing and so on. |

| Delivery time | Depends on the size and structure. Normally: 25-30 working days after 50% down payment. |

| Terms of payment | T/T, L/C, Western Union, D/A, D/P, Paypal. |

| Machine center | High speed CNC, Wire cutting, EDM, Grinder, Great Grinder, CNC milling, Drilling and milling, Stamping punching machines, injection machine, Inspection. |

| R&D | 1. Drawing design and making for products and mold; 2. Mold drawing revising; 3. Production time and quality control in each machining process. (Our ownEPR system). |

| Production | Pilot Run production and molding production can be provided. |

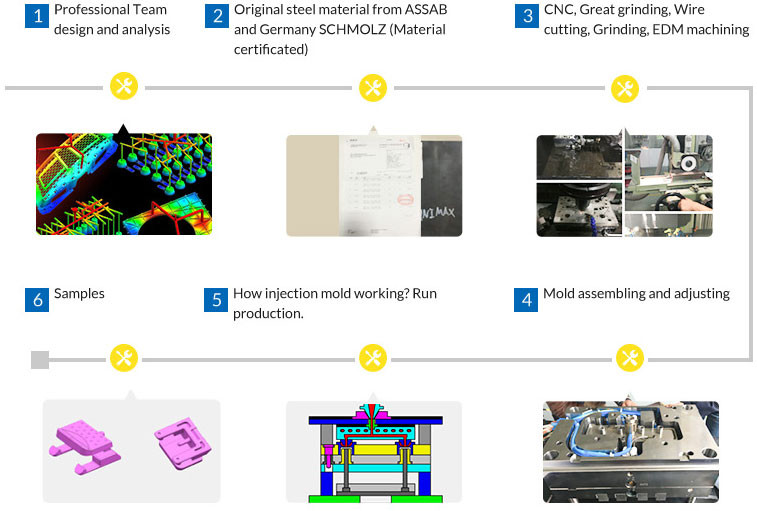

Product Flow

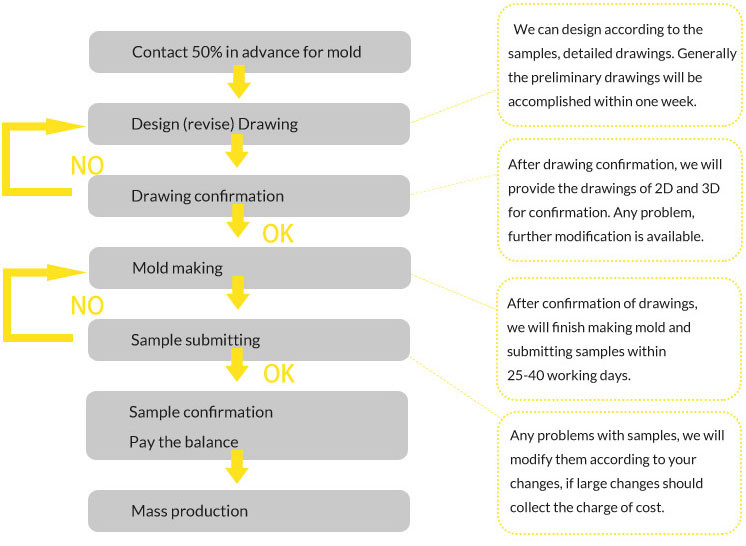

How to Customized a Mold?

A) Before sales Service

B) Production period service

C) After sales service

Our Partner

Our stamping products

Product Categories :Sheet Metal Stamping Parts

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.