Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

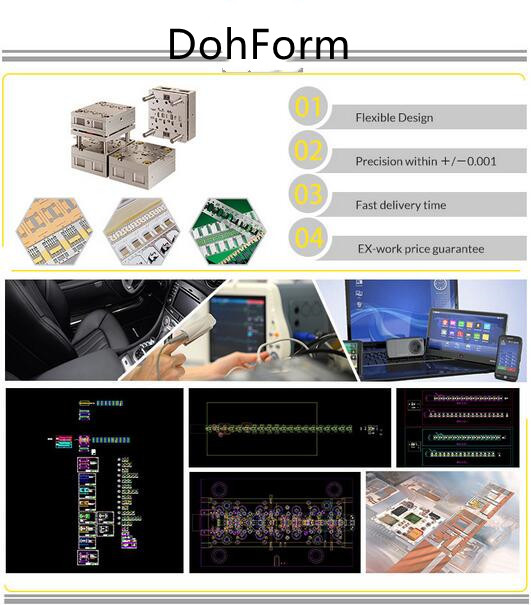

Brand: DoHform

Place Of Origin: China

Forming Method: Punching Mold, Extrusion Mould

Product Material: Metal, Steel, Aluminium, Iron, Copper

Product: Vehicle Mould, Household Appliance, Household Product

Packaging: Standard exported Wooden box packed, Fumigation process(upon required)

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability:

Port: Shanghai,Ningbo,China

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW,DDU,DDP

Mold 2D + 3D drawing Design:

| Product name | China manufacturer custom high quality precision metal progressive stamping die |

| Tooling steel material | Depend on product, we help customer to choose the suitable material. Commonly used material as below: Carbide(CD650,V3,KD20), ASP-23, ASP-60, S55C---45#55, SKD11. |

| Steel ofMold Base | Depend on product, we help customer to choose the suitable material. Commonly use S45C. |

| Mould Standard components | HASCO, MISUMI, Meusburger, DME, etc. |

| Die concept | 2-Plate Day, 3-Plate Day, Module Day |

| Mold life | Depends on the steel material and your requests. Commonly used: 50 Million to 300 Million Times |

| Stamping Product | PC Terminal, Power terminal, Press-Fit Terminal, Lead frame, SIM Spring,Connector Shield, Battery, Metal USB shell, custom stamping. |

| Surface finish | Depends on your requirements. Commonly: Texture Hatching, EDM Hatching, plating, Polishing, Diamoud Polishing, Mirror Polishing and so on. |

| Delivery time | Depends on the size and structure. Normally: 25-30 working days after 50% down payment. |

| Terms of payment | T/T, L/C, Western Union, D/A, D/P, Paypal. |

| Machine center | High speed CNC, Wire cutting, EDM, Grinder, Great Grinder, CNC milling, Drilling and milling, Stamping punching machines, injection machine, Inspection. |

| R&D | 1. Drawing design and making for products and mold; 2. Mold drawing revising; 3. Production time and quality control in each machining process. (Our ownEPR system). |

| Production | Pilot Run production and molding production can be provided. |

Product Flow

How to Customized a Mold?

A) Before sales Service

B) Production period service

C) After sales service

Our Partner

Our stamping products

Product Categories :Sheet Metal Stamping Parts

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.