Comparison of 3D printing technology and mold manufacturing

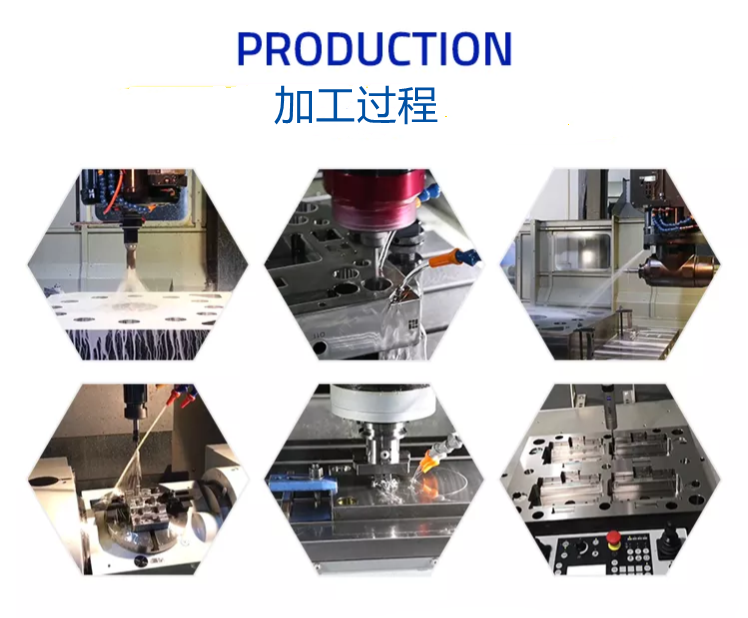

At this stage, in the manufacturing process of industrial products, mold manufacturing is mainly used as the technical framework, and the basic requirements of industrial production are met by comprehensively exploring the advantages of mold manufacturing technology.

However, from the actual situation, the cost of mold manufacturing technology is relatively high, and there is a certain degree of difficulty in operation. With the rise of personalized consumption methods, different consumers will have more diverse use requirements for industrial products.

As a result, the mold manufacturing technology needs to spend a lot of time on mold design and manufacturing, and the accuracy of mold manufacturing and the controllability of costs are becoming more and more difficult to effectively control.

Therefore, mold manufacturing technology is increasingly difficult to meet the objective needs of industrial design and processing activities in the market economy environment.

At the same time, the risk control of mold manufacturing technology is poor. Once the production quantity cannot be guaranteed, it will greatly increase the business risks faced by the enterprise and bear greater economic losses.

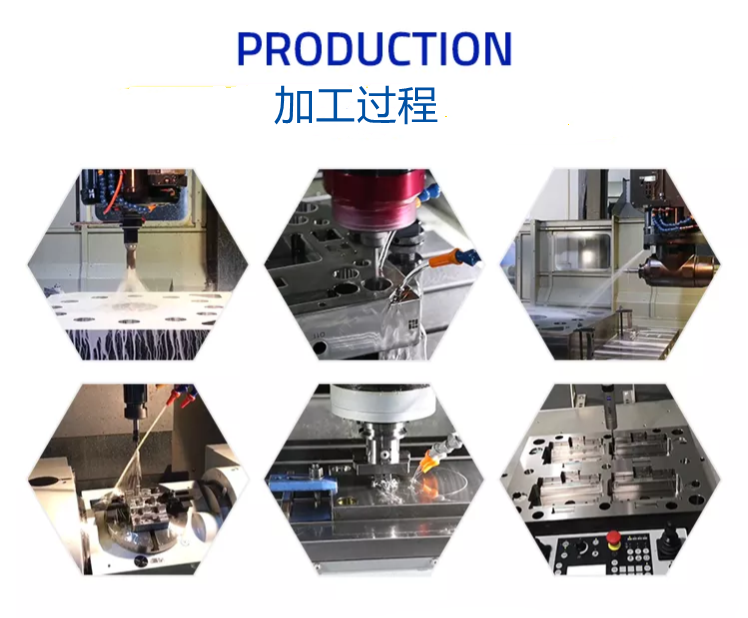

The realization of 3D printing technology in industrial design, with its own technical advantages, can optimize the design process, thereby shortening the design cycle and reducing the cost risk faced in the industrial design process, which is critical for the entire industrial design activity Impact.

3D printing technology can carry out small-scale production and market launch of industrial products. Through the collection of market responses, corresp